So, you looked over our website, or maybe you know someone in advanced manufacturing, or maybe you did a tour of our facility. Regardless, you’ve done some research and you’ve decided you really want to join our team. Where do you start?

Good news: there are several different ways you can join the skilled trades!

Circle 5 employs many different careers, so a good question to ask is: which role is right for you? Each position has its own requirements that are unique to the job. Here are a few of the careers at Circle 5 to give you an idea:

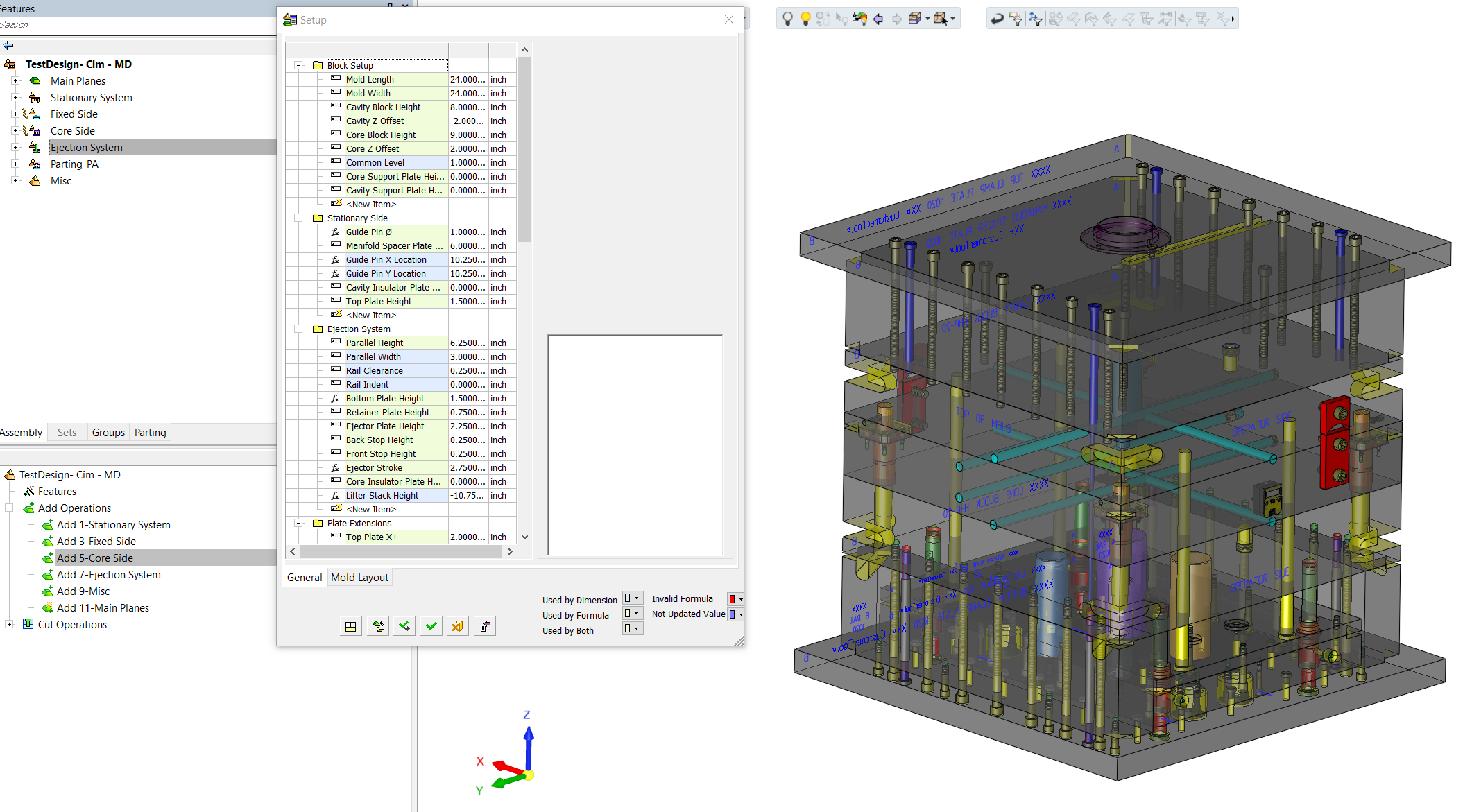

Designer – engineers the molds based on customer part data, utilizing design software such as Cimatron. They basically build the mold around the diagram of the part that the customer provides. Sounds easy right? But it’s not, our designers just make it look easy. There are hundreds of moving parts inside a plastic injection mold that the designer needs to be conscious of. They need to be able to envision the mold they’re designing in their minds in 3d. They also need to problem-solve in order get everything to fit together and work efficiently. Oftentimes the designer must collaborate with customers and team members to provide the best solutions.

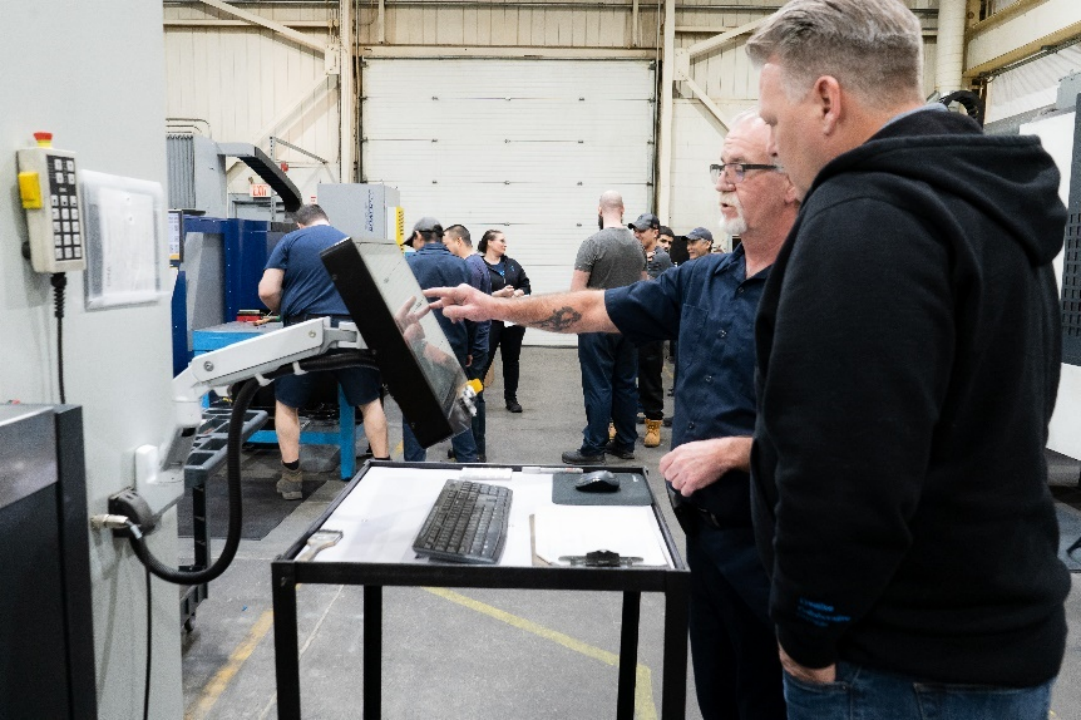

Boring Mill Operator – uses computerized CNC boring mill machines to cut steel blocks. These massive machines create holes in the steel for the moving parts that make up the inside of a mold. First the boring mill operator sets up steel blocks and plates on the machine using Fast Clamping System (FCS). Once the steel is securely in place, the operator programs cutter paths that instruct the machine on where to cut the steel. Once the program is running, they monitor the machine to ensure it runs efficiently. They work closely with the engineering department to make sure the mold is being cut to specification.

CNC Programmer – produces cutter path programs for the computerized CNC machines based on the designs produced by the design team. The programmer determines the optimal approach to machine the steel efficiently while producing the highest quality results. The programmer is responsible for developing automation of the programming to improve efficiency. Creative problem solving and being able to visualize the design in 3D helps the programmer to create the programs. Time management skills help them to plan when the programs should run in order to meet deadlines.

CNC Operator – uses the programs developed by the programmer, and takes the steel blocks to the next stage after boring mill. They operate the CNC machine to remove steel using precision cutting tools. If any issues arise, they troubleshoot the machine and make decisions to resolve problems. Attention to detail is required to make sure the machine is operating at peak performance. Some programming is required to fix any issues that may arise.

EDM Operator – runs the Electrical Discharge Machines (EDM), a machine that uses carbon electrodes or copper wire to burn shapes and fine detail into steel. The operator develops computerized programs to machine the electrodes and program the EDM machine. There is a lot of problem-solving and creativity involved to produce the high-quality work and efficient machining results. Accuracy is key for the EDM machinist while working with tight tolerances to produce the desired product. If you’re interested in learning more about EDM machines and how they work, check out our blog post here.

Polisher – is responsible for polishing the mold cavity to a mirror finish. A keen eye and attention to detail is key for the artistry required for this position. The mold cavities need to be polished within a thousandth of an inch for complete accuracy, otherwise when hot plastic is injected into the mold it will leak through the cracks or cause flaws in the finished plastic piece. Polishers work closely with each other on the molds, so they need to be able to communicate and work as a team. Some of the spaces that need polishing are in tight corners so dexterity is required to ensure a smooth finish across the surface of the mold. For more information on why this job can’t be done by machines, click here.

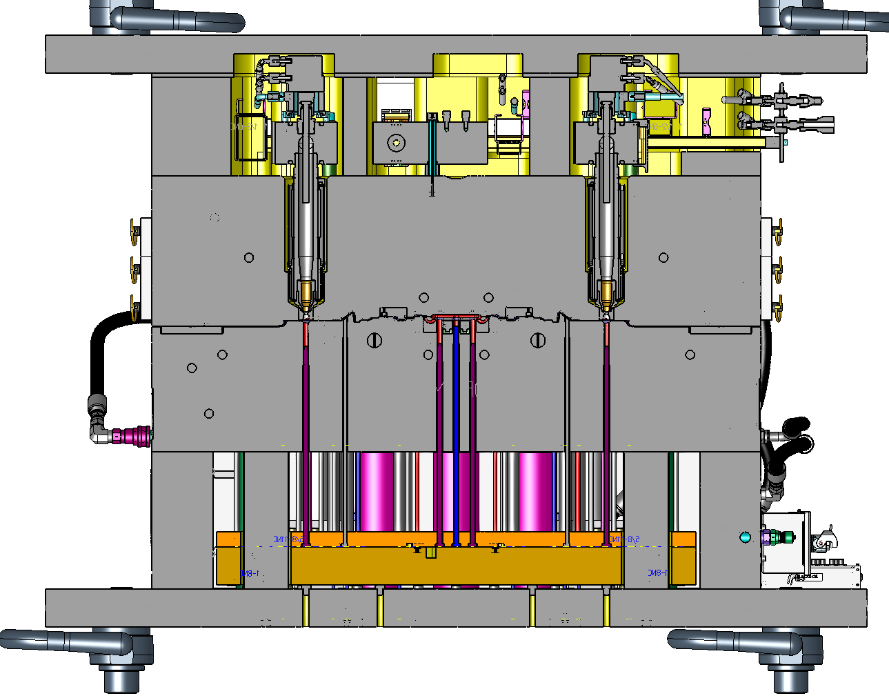

Mold Maker – oversees the entire production process. They construct the molds from finished pieces. Every mold is constructed differently, so a mold maker works in a dynamic ever-changing environment. They are responsible for assembling things like electric wiring, cooling systems, lifters and sliders, etc. For more information on what goes into a mold and what it does, click here. If pieces aren’t coming together correctly, the mold maker needs to think creatively to solve the problem. Communication is key to work closely with their team members on these complex molds. They have access to a wide variety of tools, such as: bridgeports, lathes, ceiling cranes, forklifts, and precision measuring tools to help them complete their work.

Program Manager – coordinates each mold from concept to finished product. Their job is to make sure deadlines are met and customer specifications are followed. To do this, the program manager runs meetings, attends tool tryouts, and compiles and distributes reports to the people involved. Molds cost millions of dollars, so the customer needs to feel confident that the program manager won’t let any details fall through the cracks. Program managers work closely with everyone involved in manufacturing the mold, including but not limited to: customers, contractors, mold makers, machine operators, programmers, designers, and quality inspectors.

Quality Inspector – uses a laser probe to measure the dimensional accuracy of finished steel and plastic parts to within a fraction of a millimeter. They perform calibration and maintenance on the laser machine. Part of their job is to analyze and problem-solve, using measurement data to ensure the part matches customer specifications. They will then recommend necessary corrective actions based on the inspection results. Dimensional reports are provided to the customer and internal teams. Attention to detail is integral.

These are just a small number of the people who work in a mold manufacturer. Some of our employees don’t work directly with the molds, but their roles are just as important: accountants, payroll, estimators, human resources, logistics, IT, and more.

If you’re interested in any of these roles, it’s a good idea to sit down with your high school guidance counsellor to get more information. They can help you get on the right track and show you the schooling, programs or apprenticeships you’ll need to help you succeed. The guidance counsellor can also help you apply for a co-op program with us, so you can try it out for yourself. We also have a summer student program that you can apply for through our job board.

At Circle 5, we’re committed to ushering in the next generation of skilled trades workers. Our highly skilled employees are the best equipped to pass on their knowledge. What are you waiting for? Start your career in the skilled trades TODAY!