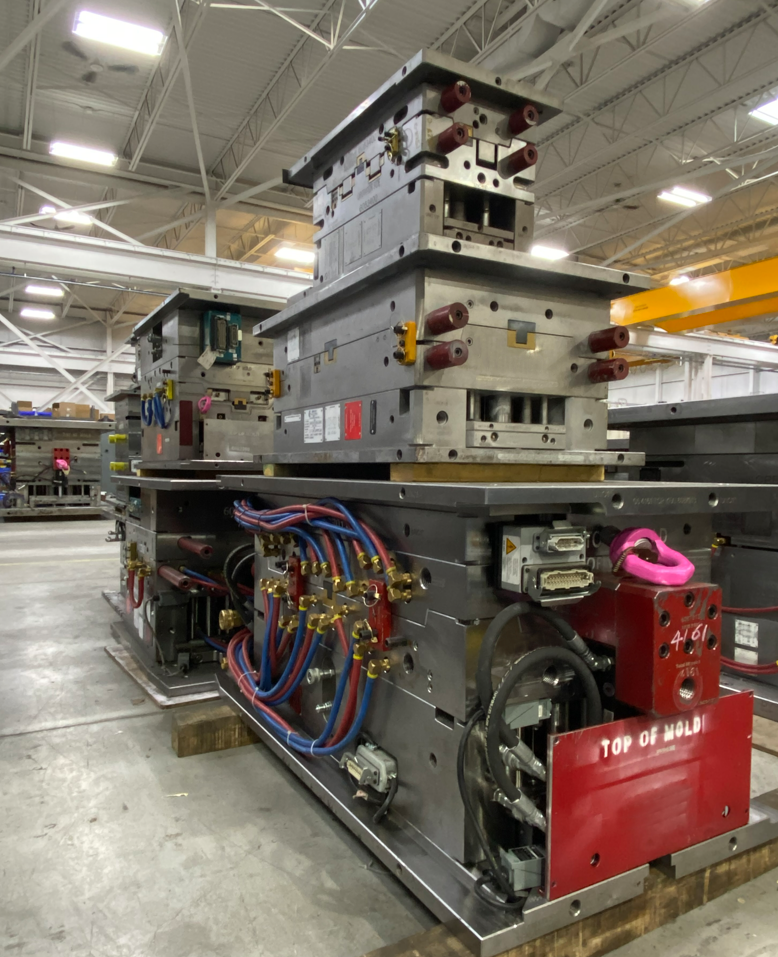

Even with advanced technology and automated machinery, hand polishing is still required for plastic injection molds to achieve the highest level of finish and quality. Here are a few reasons why hand polishing is still necessary:

- Quality and consistency: Hand polishing allows for precise and consistent results that may not be possible with automated polishing. This is because the human sense touch and sight with collective experience can detect and correct imperfections that may be missed by machines, ensuring a uniform and high-quality finish.

- Fine detail work: While machines can do the heavy lifting when it comes to polishing, hand polishing is still required for finer details. The intricate shapes of a mold often require a skilled hand to ensure that every surface is polished to perfection.

- Access to tight spaces: Some areas of a mold may be difficult or impossible for machines to reach, such as tight corners or narrow channels. Hand polishing allows for access to these areas. This ensures that every surface is polished to the same level of finish.

- Flexibility: Hand polishing allows for greater flexibility in the polishing process. A skilled moldmaker can adjust the pressure, angle, and polishing compound used to achieve the desired finish, and can quickly correct any issues that may arise during the polishing process.

- Final inspection: Hand polishing is often the final step in the moldmaking process. It allows for a final inspection to ensure that the mold is free of defects and imperfections. This can be especially important for high-precision molds that require a flawless surface finish.

Circle 5’s polishing team is best-in-class, and is ready to make your next part shine.

Circle 5 is always looking for capable and collaborative people to join our growing team. Follow the link to see a list of available opportunities.